Cast Iron CNC Rotomolded Polyethylene Kayak 3D Drawing 300000 Shots

Product Details:

| Place of Origin: | China |

| Brand Name: | Yuan Huai |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Package |

| Delivery Time: | 20 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 months |

|

Detail Information |

|||

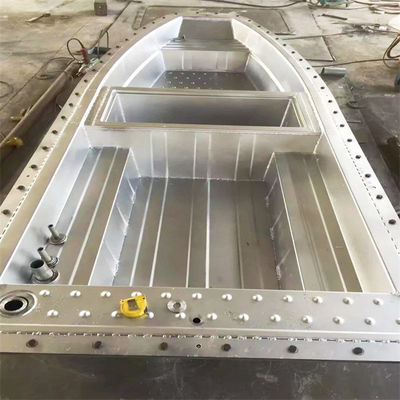

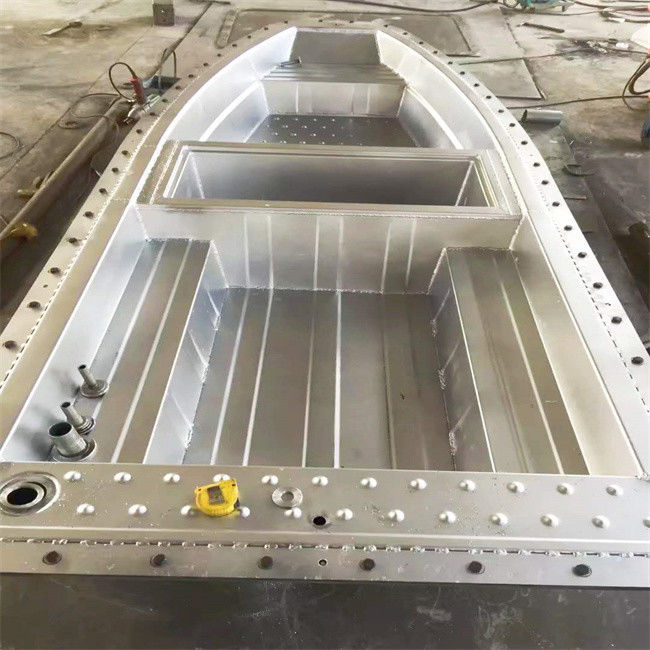

| Material Texture: | Cast Iron | Product Name: | Rotomolded Polyethylene Kayak |

|---|---|---|---|

| Size: | Customized | Mould Process: | Fully CNC Produced |

| Plastic Product Material: | Polyethylene | Appliced: | Fishing Kayak, Touring Kayak, Recreational Kayak |

| Highlight: | Cast Iron Rotomolded Polyethylene Kayak,CNC Rotomolded Polyethylene Kayak,300000 Shots roto mold kayak |

||

Product Description

Cast Iron Rotomolded Polyethylene Kayak

Product Parameter

|

Product Discription

The rotational molding process and raw materials are the key determinants. The raw materials for rotational molding are mostly powder shape with a apparent low density, and its volume is about three times larger than that after crystallization.

Therefore, to make the raw powder fully cover the lumen surface of during rotational molding, the space with three times the wall thickness between the walls of rotational molding products is necessary to reserve at least. That is, even if the distance between the walls of rotational molding products reaches three times the average wall thickness, the powder filled in it just becomes two walls after melting.

Product Advantages

1. The plastic with good thermal stability is not decompose for a long time at high temperature and the properties of raw materials will not be changed or reduced.

2. The plastic varieties that can meet these requirements, polyethylene (PE) with the highest degree of compliance and the best performance has the largest proportion of polyethylene in plastic raw materials, followed by polyvinyl chloride (PVC). In addition to the above two kinds of plastics, some kinds of material also meet these requirements under certain conditions, such as nylon (PA), polypropylene (PP), polycarboxylate (PC), polylactic acid (PLA), polymethylmethacrylate (POM), fluoropolymer, EVA, PBT, TPU, etc.

FAQ

1. Can you provide sample?

Yes, please feel free to tell us, also your own design is welcome to make sample for you, After confirming the authenticity of your company, we are willing to provide small quantities of free samples.

2. What types of rotomolding machines do you manufacture?

It is fast and easy to start once you can send your product drawing or picture with size or sample to us! What is more, we will do more works to help you get the perfect product, such as:

a.Product material, structure, application,thickness ,inserts;

b.Mould material, locking system, hoist safety,machine placement, demoulding effciency;

c.Sample tes. All above is respect to customer' s initial design or work under confirmed modifcation, a professional manager to follow up from start to final accept.